Revêtement de barrage en géomembrane en polyéthylène haute densité

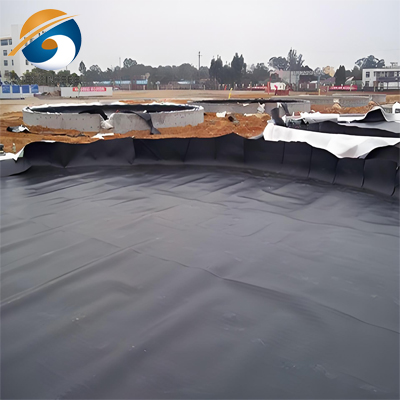

La géomembrane en polyéthylène haute densité joue un rôle important comme membrane anti-infiltration dans la construction de barrages. Elle est généralement utilisée comme couche principale anti-infiltration pour prévenir les fuites d'eau et assurer la sécurité structurelle du barrage. La géomembrane en PEHD présente une excellente résistance à la perméabilité, à l'érosion chimique et au vieillissement, ce qui lui permet de bloquer les cours d'eau de manière fiable et durable. Elle constitue un matériau idéal pour le contrôle des infiltrations. De plus, elle est facile à installer et offre une grande efficacité de construction, ce qui permet de réduire considérablement les coûts de construction des barrages. Dans la construction de barrages, la géomembrane en polyéthylène haute densité assure la sécurité du barrage et améliore les coûts de construction. Elle est largement utilisée dans ce domaine.

À l’ère moderne des infrastructures et de la protection de l’environnement,Revêtement de barrage en géomembrane en polyéthylène haute densitéest devenu la référence du secteur pour l'étanchéité des barrages et le confinement des eaux. Conçu pour des performances exceptionnelles, ce revêtement offre une durabilité, une résistance chimique et une imperméabilité inégalées, ce qui le rend idéal pour une large gamme d'applications de barrages et de réservoirs.

Si vous recherchez une solution fiable, rentable et écologique pour la construction ou la réhabilitation de barrages,Revêtement de barrage en géomembrane en polyéthylène haute densitéest votre réponse. Cet article vous explique tout ce que vous devez savoir sur ce produit innovant : ses caractéristiques, ses avantages, ses processus d'installation et pourquoi il est le choix numéro un des ingénieurs et des experts en environnement.

Qu'est-ce qu'une membrane géomembrane en polyéthylène haute densité pour barrage ?

UNRevêtement de barrage en géomembrane en polyéthylène haute densitéIl s'agit d'un revêtement ou d'une barrière synthétique en résine de polyéthylène haute densité (PEHD). Il est principalement utilisé pour contrôler la migration des fluides ou des gaz dans diverses applications techniques et environnementales. Sa résistance élevée à la traction et sa stabilité chimique le rendent particulièrement adapté au revêtement des barrages, où la performance à long terme est essentielle.

Avec une densité supérieure à 0,94 g/cm³, les géomembranes en PEHD offrent une barrière robuste et résistante aux perforations, garantissant une étanchéité parfaite. Conçues pour résister aux intempéries, aux rayons UV et à une exposition prolongée aux produits chimiques, elles constituent un choix privilégié pour les structures permanentes de confinement des eaux.

Pourquoi choisir un revêtement de barrage en géomembrane en polyéthylène haute densité ?

LeRevêtement de barrage en géomembrane en polyéthylène haute densitéest favorisé pour de nombreuses raisons :

1.Imperméabilité exceptionnelle

La fonction première d'un revêtement de barrage est d'empêcher les infiltrations d'eau. Les géomembranes en PEHD offrent une excellente imperméabilité, garantissant ainsi la rétention de l'eau dans le réservoir ou le bassin du barrage.

2.Résistance chimique supérieure

Le PEHD est chimiquement inerte, ce qui rend le revêtement résistant aux acides, aux bases et aux hydrocarbures. Cette propriété est particulièrement utile dans les régions où la contamination chimique des sources d'eau est préoccupante.

3.Résistance aux UV et aux intempéries

LeRevêtement de barrage en géomembrane en polyéthylène haute densitéest stabilisé aux UV, offrant une durabilité à long terme même lorsqu'il est exposé à la lumière directe du soleil et à des températures extrêmes.

4.Haute résistance à la traction et à la perforation

Les géomembranes en PEHD peuvent supporter de lourdes charges et contraintes mécaniques sans se déchirer. Cette durabilité est essentielle pour les barrages de grande envergure, dont l'intégrité doit être préservée pendant des décennies.

5.Rentabilité

Par rapport aux matériaux de revêtement traditionnels tels que le béton ou l'argile, leRevêtement de barrage en géomembrane en polyéthylène haute densitéoffre une solution plus économique avec des coûts de maintenance réduits.

Applications de la membrane géomembrane en polyéthylène haute densité pour barrages

La polyvalence duRevêtement de barrage en géomembrane en polyéthylène haute densitépermet de l'utiliser dans un large éventail d'applications :

Barrages en terre et en enrochements

Étangs d'irrigation agricole

Réservoirs hydroélectriques

Bassins de rétention d'eau

Confinement des eaux usées industrielles

Bassins de collecte des lixiviats des décharges

Qu'il s'agisse de la construction de nouveaux barrages ou de la modernisation de structures existantes, les géomembranes en PEHD sont la solution idéale pour l'étanchéité à l'eau et la sécurité environnementale.

Directives d'installation pour revêtement de barrage en géomembrane de polyéthylène haute densité

Une installation correcte est essentielle à la performance de tout système de géomembrane. Voici un aperçu général de l'installation d'une géomembrane.Revêtement de barrage en géomembrane en polyéthylène haute densité:

1.Préparation des surfaces

Dégagez le sous-sol de tous les objets tranchants, racines ou pierres.

Assurez-vous que la surface est lisse et compactée.

2.Déroulement et positionnement

Déroulez soigneusement la doublure en PEHD pour éviter qu'elle ne s'étire ou ne se déchire.

Positionner le liner selon le plan d'aménagement du barrage en tenant compte des chevauchements.

3.Soudage et couture

Utilisez des machines de soudage par coin chaud ou par extrusion pour coller les feuilles.

Effectuer des tests de contrôle qualité tels que des tests de boîte à vide et de pression d'air.

4.Ancrage et couverture

Ancrez les bords dans les tranchées pour éviter le soulèvement.

Dans certains cas, recouvrez de terre ou de ballast pour protéger contre les dommages physiques.

Spécifications techniques de la membrane géomembrane en polyéthylène haute densité pour barrage

| Propriété | Valeur standard |

|---|---|

| Épaisseur | 0,5 mm à 3,0 mm |

| Densité | ≥ 0,94 g/cm³ |

| Résistance à la traction | ≥ 25 MPa |

| Allongement à la rupture | ≥ 700% |

| Résistance à la perforation | ≥ 600 N |

| Teneur en noir de carbone | 2,0 – 3,0 % |

| Résistance aux UV (arc au xénon) | ≥ 90 % de résistance conservée (5 000 h) |

| Résistance chimique | Excellent |

Consultez toujours la fiche technique du fabricant pour connaître les spécifications exactes adaptées à votre projet.

Conformité environnementale et réglementaire

L’un des principaux avantages de l’utilisation d’unRevêtement de barrage en géomembrane en polyéthylène haute densitéest conforme aux réglementations environnementales internationales. Les géomembranes en PEHD sont :

Non toxique et respectueux de l'environnement

Approuvé par des agences telles que l'EPA et l'ISO

Réutilisables et recyclables à la fin de leur cycle de vie

Ces caractéristiques les rendent idéales pour les projets avec des objectifs de durabilité et des exigences de conformité stricts.

Comment choisir la bonne membrane géomembrane en polyéthylène haute densité pour votre barrage

Lors du choix d'unRevêtement de barrage en géomembrane en polyéthylène haute densité, tenez compte des facteurs suivants :

Taille et emplacement du projet: Terrain, climat et charge prévue.

Exigences d'épaisseur:Les projets plus lourds nécessitent des revêtements plus épais.

Exposition chimique:Type et concentration des contaminants potentiels.

Exposition aux UV:Les projets dans les régions ensoleillées peuvent nécessiter une stabilisation UV améliorée.

Budget et coûts du cycle de vie:Équilibre entre l’investissement initial et l’épargne à long terme.

Consulter un fournisseur de géomembranes qualifié ou un ingénieur civil peut vous aider à optimiser votre sélection.

Entretien et longévité

LeRevêtement de barrage en géomembrane en polyéthylène haute densitéest réputé pour son faible entretien. Des inspections régulières et des réparations mineures peuvent garantir l'intégrité du revêtement pendant plus de 30 ans. Voici quelques conseils d'entretien clés :

Inspections régulières pour détecter les signes de dommages physiques

Réparation rapide des déchirures à l'aide de patchs HDPE compatibles

Contrôle périodique des coutures et des bords

Contrôle de la végétation autour de la zone du barrage pour empêcher l'intrusion des racines

Où acheter une membrane géomembrane en polyéthylène haute densité pour barrage

Pour garantir la qualité et la conformité, achetez votreRevêtement de barrage en géomembrane en polyéthylène haute densitéauprès de fabricants certifiés ayant fait leurs preuves dans le secteur. Recherchez des fournisseurs qui proposent :

Produits certifiés ISO et ASTM

Accompagnement et supervision de l'installation

Couverture de garantie complète

Consultations techniques et visites de sites

Évitez les alternatives peu coûteuses et non testées qui pourraient compromettre l’intégrité structurelle et la sécurité environnementale de votre projet.

Conclusion

LeRevêtement de barrage en géomembrane en polyéthylène haute densitéest une solution de pointe pour le revêtement de barrages, alliant imperméabilité, durabilité et respect de l'environnement exceptionnels. Que vous construisiez un nouveau barrage ou réhabilitiez un réservoir vieillissant, les géomembranes en PEHD offrent des performances inégalées à un prix abordable.

En choisissant unRevêtement de barrage en géomembrane en polyéthylène haute densité, vous investissez dans un produit qui répond aux normes les plus élevées d'ingénierie, de durabilité et de fiabilité à long terme.

Paramètre

lt |

Article détaillé |

Unité |

Standard |

Fréquence des tests |

GS075 |

GS010 |

GS015 |

GS020 |

GS030 |

Mécanique Propriétés |

Épaisseur |

mm |

199 Dh |

par rouleau |

0.75 |

1.00 |

1.50 |

2.00 |

3.00 |

Densité |

g/cc |

D1505/D792 |

90 000 kg |

0.94 |

|||||

Propriétés de traction |

|||||||||

Limite d'élasticité |

KN/m |

Dazza Type IV |

9 000 kg |

11 |

15 |

22 |

29 |

44 |

|

Résistance à la rupture |

KN/m |

20 |

27 |

40 |

53 |

80 |

|||

Allongement du rendement |

% |

12 |

12 |

12 |

12 |

12 |

|||

Allongement de rupture |

% |

700 |

700 |

700 |

700 |

700 |

|||

Résistance à la déchirure |

N |

D1004 |

20 000 kg |

93 |

125 |

187 |

249 |

374 |

|

Résistance à la perforation |

N |

D4883 |

20 000 kg |

240 |

320 |

480 |

640 |

960 |

|

Résistance aux fissures de contrainte |

Heure. |

C'est vrai |

par GRl GM-10 |

300 heures |

|||||

Teneur en noir de carbone |

% |

D4218 |

9 000 kg |

2,0-3,0% |

|||||

Dispersion de noir de carbone |

D5596 |

20 000 kg |

Pour 10 vues différentes : 9 dans les catégories 1 ou 2 et 1 dans la catégorie 3 |

||||||

Référence Propriétés |

Temps d'induction oxydative |

||||||||

OlT standard |

min |

Bon sang |

90 000 kg |

100 minutes |

|||||

OlT haute pression

|

D5885 |

90 000 kg |

400 min |

||||||

Vieillissement au four à 85°C conservé après 90 jours

|

% |

d5721 |

pour chacun formulation |

55% |

|||||

OlT standard |

Bon sang |

80% |

|||||||

OlT haute pression |

D5885 |

80% |

|||||||

Résistance aux UV |

|||||||||

Haute pression OlT_% conservée après 1600 h |

% |

D5885 |

pour chacun formulation |

50% |

|||||

Taille du rouleau |

Largeur du rouleau |

m |

7 |

7 |

7 |

7 |

7 |

||

Longueur du rouleau |

m |

280 |

210 |

140 |

105 |

70 |

|||

Stabilité de la taille |

% |

2% |

|||||||

Avantages de la membrane géomembrane en polyéthylène haute densité pour barrage